Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Choosing the right fence supplier can make or break a project. Imagine the frustration of a single delayed shipment or poor-quality fence panels derailing your schedule. For B2B importers – wholesalers, resellers, and contractors – finding a trustworthy overseas fence factory is vital for peace of mind. This guide walks you through proven steps to vet manufacturers, ensuring your fence orders – whether ASA-panel or WPC-panel fences with aluminum frames – arrive on time and in top shape.

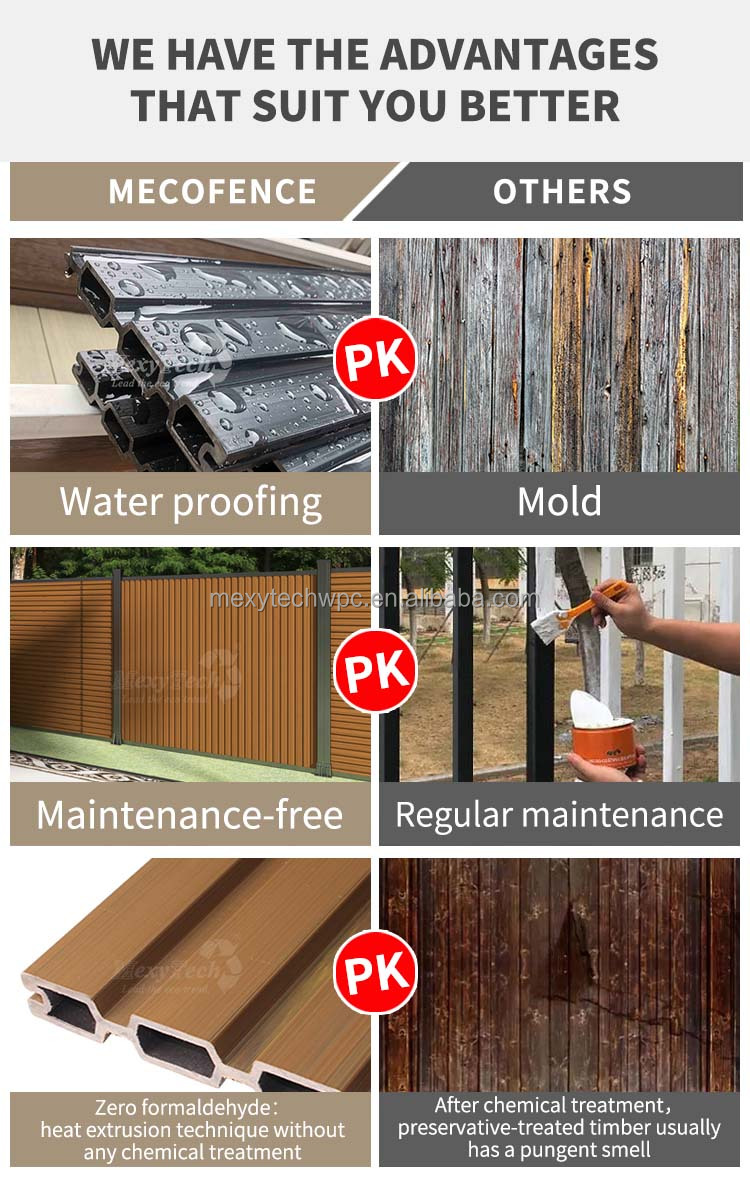

First, look at the factory’s track record. An established manufacturer often offers both material expertise and design innovation. MecoFence excels in both ASA-panel and wood-plastic-composite (WPC) panel fences, all mounted on rugged aluminum posts. Their FlowShield line, for instance, is crafted from marine-grade aluminum and UV-stabilized polymers to ensure corrosion resistance. Their Dual Tone 3D Slat Wall Fence illustrates this capability: it blends high-style (a two-tone finish) with engineered stability.

Reputable suppliers invest in engineering. MecoFence’s Dual Tone Slat Wall Fence product (see image) is precision-extruded for strength, merging a modern two-color look with patented interlocking panels. In other words, their fence boards aren’t just pretty – they’re built to last in tough environments. When evaluating a supplier, request samples to inspect material quality (grain texture, solidity) and design features. Ask if their panels use UV-stabilized polymers or marine-grade aluminum frames.

Next, use a checklist to compare potential suppliers. Start with these evaluation strategies:

Q: How can I verify a fence factory’s credibility overseas?

A: Look for company certifications (e.g. ISO 9001) or third-party audits that demonstrate quality processes. Request compliance documents and collect references from other importers or wholesalers. If possible, hire a local agent or inspection service to audit the factory’s output before shipment. Real photos or videos of the production line and finished panels can also provide assurance.

Q: What should I look for in product samples?

A: Inspect build quality: panels should fit tightly, colors must be uniform, and surfaces smooth. Test a sample’s weight and strength (e.g. try bending it slightly) to assess material density. Verify that aluminum posts or frames are straight, square, and well-coated (no chips or rust spots). These quick checks reveal a lot about consistency and manufacturing standards.

Q: How do I handle shipping (FOB) and receiving?

A: With FOB (Free on Board) shipping, the factory loads your order on the ship at the port of origin. From that point, you (the buyer) take ownership and manage the sea freight and insurance. The seller covers costs and risks up to loading the goods on board and provides the Bill of Lading. Essentially, you pay for ocean freight and import duties, while the seller handles export clearance to the dock. Ensure the contract spells out which port is FOB and who arranges and pays for ocean freight, customs, and delivery.

Q: What is the lead time for overseas fence orders?

A: Lead times vary by order size and customization. A good supplier will quote both production time and shipping time. For example, a large order of custom WPC panels might take several weeks to manufacture, plus ~30–45 days for sea transit. Always build in extra days for final inspections and any unexpected delays.

In summary, follow this six-step approach:

Define Requirements: Specify fence material (ASA or WPC), panel dimensions, finish, and quantity. Decide if you need frames or posts included.

Shortlist Factories: Use trade directories, B2B platforms (like Alibaba), or referrals to find candidates. Focus on suppliers with experience in your fence style or material.

Request Information: Ask each candidate for brochures, factory photos, and product links (such as MecoFence’s Dual Tone 3D Slat Wall Fence) along with detailed FOB pricing.

Vet Rigorously: Verify business licenses and certifications. Request and test samples. Check references and, if possible, tour the factory. Clarify payment terms and logistics early.

Negotiate Contract: Set clear contract terms for lead times, incoterms (e.g. FOB), payment schedule, and quality standards (tolerances, finishes, etc.).

Finalize Order: Place the order only when you feel confident in the factory’s reliability and have completed all negotiations and inspections.

Choosing a fence supplier is both an art and a science. By combining fact-based checks (certificates, sample tests, references) with trust-building human factors (clear communication, transparency), you can turn a risky import into a confident partnership. Remember, a strong supplier relationship means your fence panels – whether they’re sleek ASA-slatted panels or warm wood-look WPC boards – will arrive securely and ready to impress. Indeed, MecoFence’s commitment to quality exemplifies how careful sourcing pays off.